I-DIN912 H59 H62 I-Brass Hex Socket Cup Isikulufu Sekhanda

I-DIN912 H59 H62 I-Brass Hex Socket Cup Isikulufu Sekhanda

Incazelo

SHESHAImpendulo

SHESHAIkhotheshini

SHESHAUkulethwa

ILUNGELE UKULETHWA NGOMKHUMBA

10000+ I-SKU endaweni yokugcina impahla

Sizibophezela ezintweni ze-RTS:

70% izinto ezilethiwe ezinsukwini ezi-5

80% izinto ezilethiwe phakathi kwezinsuku ezingu-7

90% izinto ezilethiwephakathi kwezinsuku eziyi-10

Ama-oda amaningi, sicela uxhumane nesevisi yamakhasimende

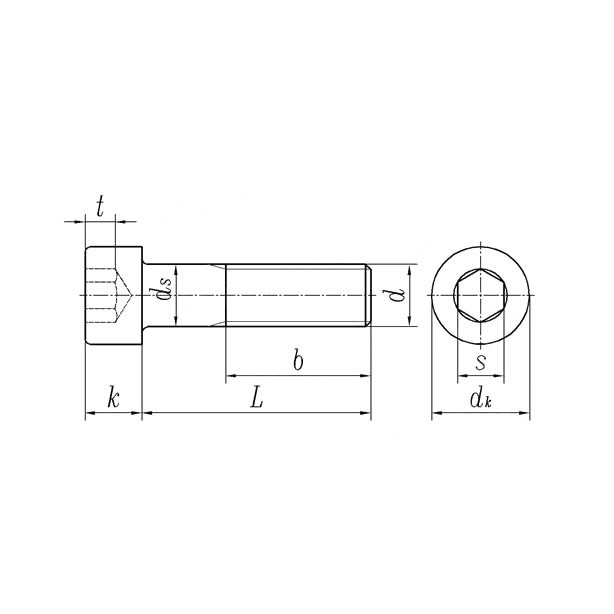

| d | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | |

| P | Intambo eqinile | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 |

| Intambo enhle | / | / | / | / | / | / | / | / | 1 | 1.25 | 1.5 | 1.5 | 1.5 | 2 | 2 | |

| Intambo Enhle Kakhulu | / | / | / | / | / | / | / | / | / | 1 | 1.25 | / | / | 1.5 | 1.5 | |

| b | Inani lesithenjwa | 14 | 15 | 16 | 17 | 18 | 20 | 22 | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 |

| dk | I-Max (Bushelelezi) | 2.6 | 3 | 3.8 | 4.5 | 5.5 | 7 | 8.5 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 |

| UMax (Knurl*) | 2.74 | 3.14 | 3.98 | 4.68 | 5.68 | 7.22 | 8.72 | 10.22 | 13.27 | 16.27 | 18.27 | 21.33 | 24.33 | 27.33 | 30.33 | |

| Okuncane | 2.46 | 2.86 | 3.62 | 4.32 | 5.32 | 6.78 | 8.28 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | |

| ds | Ubukhulu | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Okuncane | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | |

| k | Ubukhulu | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Okuncane | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.7 | 7.64 | 9.64 | 11.57 | 13.57 | 15.57 | 17.57 | 19.48 | |

| s | Ngokuzisholo | 1.3 | 1.5 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 14 | 17 |

| Okuncane | 1.32 | 1.52 | 1.52 | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 12.032 | 14.032 | 14.032 | 17.05 | |

| Ubukhulu | 1.36 | 1.56 | 1.56 | 2.06 | 2.58 | 3.08 | 4.095 | 5.14 | 6.14 | 8.175 | 10.175 | 12.212 | 14.212 | 14.212 | 17.23 | |

| t | Okuncane | 0.6 | 0.7 | 1 | 1.1 | 1.3 | 2 | 2.5 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Ubude bomucu=b | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| d | (M22) | M24 | (M27) | M30 | (M33) | M36 | M42 | M48 | M56 | M64 | M72 | M80 | M90 | M100 | |

| P | Intambo eqinile | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 6 | 6 | 6 | 6 |

| Intambo enhle | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Intambo Enhle Kakhulu | 1.5 | / | / | / | / | / | / | / | / | / | / | / | / | / | |

| b | Inani lesithenjwa | 56 | 60 | 66 | 72 | 78 | 84 | 96 | 108 | 124 | 140 | 156 | 172 | 192 | 212 |

| dk | I-Max (Bushelelezi) | 33 | 36 | 40 | 45 | 50 | 54 | 63 | 72 | 84 | 96 | 108 | 120 | 135 | 150 |

| UMax (Knurl*) | 33.39 | 36.39 | 40.39 | 45.39 | 50.39 | 54.46 | 63.46 | 72.46 | 84.54 | 96.54 | 108.54 | 120.54 | 135.63 | 150.63 | |

| Okuncane | 32.61 | 35.61 | 39.61 | 44.61 | 49.61 | 53.54 | 62.54 | 71.54 | 83.46 | 95.46 | 107.46 | 119.46 | 134.37 | 149.37 | |

| ds | Ubukhulu | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 |

| Okuncane | 21.67 | 23.67 | 26.67 | 29.67 | 32.61 | 35.61 | 41.61 | 47.61 | 55.54 | 63.54 | 71.54 | 79.54 | 89.46 | 99.46 | |

| k | Ubukhulu | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 |

| Okuncane | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 41.38 | 47.38 | 56.26 | 63.26 | 71.26 | 79.26 | 89.13 | 99.13 | |

| s | Ngokuzisholo | 17 | 19 | 19 | 22 | 24 | 27 | 32 | 36 | 41 | 46 | 55 | 65 | 75 | 85 |

| Okuncane | 17.05 | 19.065 | 19.065 | 22.065 | 24.065 | 27.065 | 32.08 | 36.08 | 41.08 | 46.08 | 55.1 | 65.1 | 75.1 | 85.12 | |

| Ubukhulu | 17.23 | 19.275 | 19.275 | 22.275 | 24.275 | 27.275 | 32.33 | 36.33 | 41.33 | 46.33 | 55.4 | 65.4 | 75.4 | 85.47 | |

| t | Okuncane | 11 | 12 | 13.5 | 15.5 | 18 | 19 | 24 | 28 | 34 | 38 | 43 | 48 | 54 | 60 |

| Ubude bomucu=b | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

Imininingwane yokudweba

Uyini umehluko phakathi kweCopper, Brass, Bronze?

Ithusi, Ithusi kanye Nethusi, okungaziwa ngokuthi "Izinsimbi Ezibomvu", kungase kubonakale kufana ekuqaleni. Kodwa empeleni banomehluko omningi kusici, ukusebenza nokunye.

Ithusi

I-Copper isetshenziswa emikhiqizweni eminingi ngenxa ye-conductivity yayo enhle kakhulu kagesi neyokushisa, amandla amahle, ukwakheka okuhle nokumelana nokugqwala. Ukufakwa kwamapayipi namapayipi kuvamise ukukhiqizwa kusukela kulezi zinsimbi ngenxa yokumelana nokugqwala kwazo. Zingathengiswa kalula futhi zenziwe nge-brazed, futhi eziningi zingashiswa ngegesi ehlukahlukene, i-arc nezindlela zokumelana. Zingapholishwa futhi zifakwe cishe noma yikuphi ukuthungwa nokucwebezela okufunayo.

Kunamabanga e-Copper engaxutshiwe, futhi angahluka ngenani lokungcola okuqukethwe. Amamaki ethusi angenawo umoya-mpilo asetshenziswa ikakhulukazi emisebenzini lapho kudingeka khona ukuhanjiswa okuphezulu kanye ne-ductility.

Enye yezinto ezibaluleke kakhulu zethusi yikhono layo lokulwa nama-bacteria. Ngemva kokuhlolwa okubanzi kwama-antimicrobial yi-Environmental Protection Agency, kwatholakala ukuthi ama-alloys ethusi angama-355, kuhlanganise nobhedu amaningi, atholakale ebulala amagciwane angaphezu kwama-99.9% phakathi namahora amabili okuxhumana. Ukungcoliswa okuvamile kwatholakala ukuthi akukhinyabezi ukusebenza kwe-antimicrobial.

Izicelo zethusi

I-Copper yayingenye yezinsimbi zokuqala ezatholwa. AmaGreki namaRoma akwenza kwaba amathuluzi noma imihlobiso, futhi kukhona ngisho nemininingwane yomlando ebonisa ukusetshenziswa kwethusi ukuze kubulawe amagciwane amanxeba futhi kuhlanzeke namanzi okuphuza. Namuhla itholakala kakhulu ezintweni zikagesi ezifana nezintambo ngenxa yekhono layo lokuqhuba ugesi ngempumelelo.

Ithusi

Ithusi ngokuyinhloko iyingxubevange equkethe ithusi elinezinc. Ama-Brasses angaba namanani ahlukahlukene we-zinc noma ezinye izakhi ezingeziwe. Lezi zingxube ezihlukahlukene zikhiqiza izakhiwo eziningi ezihlukahlukene kanye nokuhlukahluka kombala. Amanani anyukile e-zinc anikeza impahla amandla athuthukisiwe kanye ne-ductility. Ithusi lingahluka ngombala ukusuka kobomvu kuye kophuzi kuye ngenani le-zinc elingezwe ku-alloy.

Uma okuqukethwe kwe-zinc yethusi kusuka ku-32% kuya ku-39%, kuzoba namandla okusebenza okushisa kodwa ukusebenza okubandayo kuzokhawulelwa.

Uma ithusi liqukethe ngaphezu kwe-39% zinc (isibonelo - i-Muntz Metal), izoba namandla aphezulu kanye ne-ductility ephansi (emazingeni okushisa asekamelweni).

Izicelo Zethusi

I-Brass ijwayele ukusetshenziselwa izinjongo zokuhlobisa ikakhulukazi ngenxa yokufana kwayo negolide. Ibuye isetshenziswe ngokujwayelekile ukwenza izinsimbi zomculo ngenxa yokusebenza kwayo okuphezulu nokuqina.

Ibhulonzi

I-bronze ingxubevange equkethe ngokuyinhloko ithusi kanye nokwengezwa kwezinye izithako. Ezimweni eziningi isithako esingeziwe ngokuvamile siyithayini, kodwa i-arsenic, i-phosphorus, i-aluminium, i-manganese, ne-silicon nayo ingasetshenziswa ukukhiqiza izici ezihlukene endabeni. Zonke lezi zithako zikhiqiza ingxubevange enzima kakhulu kunethusi iyodwa.

Ibhulonzi libonakala ngombala walo ofiphele nosagolide. Ungakwazi futhi ukubona umehluko phakathi kwethusi nethusi ngoba i-bronze izoba namasongo amnyama ebusweni bayo.

Izicelo Zethusi

I-bronze isetshenziswa ekwakhiweni kwezithombe eziqoshiwe, izinsimbi zomculo nezindondo, nasezintweni ezisetshenziswa ezimbonini ezifana nama-bushings nama-bearings, lapho insimbi yayo ephansi ekungqubuzaneni kwensimbi iyinzuzo. I-bronze nayo inezinhlelo zokusebenza ze-nautical ngenxa yokumelana kwayo nokugqwala.

Ukupakisha

Mayelana NATHI

* Umdwebo olandelayo ukhomba ama-incoterms ohwebo ahlukene. Sicela ukhethe oyithandayo.

OKUSHISAYO OKUDAYISWA

Ikhwalithi Okokuqala, Ukuphepha Kuqinisekisiwe