I-DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Ibanga 8.8 10.9

I-DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Ibanga 8.8 10.9

Incazelo

SHESHAImpendulo

SHESHAIkhotheshini

SHESHAUkulethwa

ILUNGELE UKULETHWA NGOMKHUMBA

10000+ I-SKU endaweni yokugcina impahla

Sizibophezela ezintweni ze-RTS:

70% izinto ezilethiwe ezinsukwini ezi-5

80% izinto ezilethiwe phakathi kwezinsuku ezingu-7

90% izinto ezilethiwephakathi kwezinsuku eziyi-10

Ama-oda amaningi, sicela uxhumane nesevisi yamakhasimende

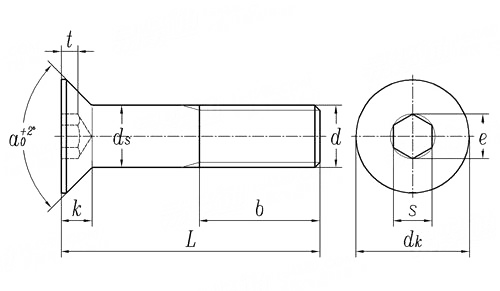

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | Iphimbo | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | inani.(+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 60° | 60° |

| b | L≤125mm | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125<L ≤200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L>200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | Ubukhulu=Izibizo | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Okuncane | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | Ubukhulu=Izibizo | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Okuncane | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | Okuncane | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | Ubukhulu | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Ngokuzisholo | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Okuncane | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| Ubukhulu | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | Ubukhulu=Izibizo | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| Okuncane | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

Incazelo yemininingwane

Izinsimbi eziqinile eziphakeme zizokhiqiza ukucwebezela lapho zifakwe uthayela. Udinga ukunakwa okukhethekile.

I-hydrogen embrittlement ngokuvamile ibonakala ngokuphuka kwesikhashana ngaphansi kwengcindezi. Kube khona iziphethu zezimoto, amawasha, izikulufu, iziphethu zeshidi nezinye izingxenye zikathayela, emahoreni ambalwa ngemva kokwephulwa komhlangano, isilinganiso sokuphuka singu-40% ~ 50%. Enqubweni yokusebenzisa izingxenye ze-cadmium-plated zomkhiqizo okhethekile, kwaba nokuqhekeka kwe-batch crack, futhi inkinga yokhiye kazwelonke yaxazululwa futhi kwenziwa inqubo eqinile ye-dehydrogenation. Ngaphezu kwalokho, kukhona ezinye embrittlement hydrogen akubonisi ukubambezeleka mkhuba ukuphuka, njengokuthi: electroplating isiphanyeko (insimbi wire, ucingo lwethusi) ngenxa izikhathi eziningi electroplating futhi pickling plating, Ukungena hydrogen kubi kakhulu, ngokuvamile avele ekusetshenzisweni ukugoqa kuzokwenzeka brittle fracture mkhuba; I-mandrel ye-shotgun, ngemva kwezikhathi eziningana ze-chroming, yawela phansi futhi yaphuka; Ezinye izingxenye ezicishiwe (ukucindezeleka okukhulu kwangaphakathi) zizoqhekeka lapho zikhetha. Lezi zingxenye zine-hydrogenated kakhulu futhi ziyaqhekeka ngaphandle kokucindezeleka kwangaphandle, ezingasakwazi ukusetshenziselwa ukubuyisela ukuqina kwangempela nge-dehydrogenation.

Ukuphakama kwamandla ezinto ezibonakalayo, kukhulu ukuzwela kwe-hydrogen embrittlement. Lona umqondo oyisisekelo okufanele ucaciswe ochwepheshe bokwelapha okungaphezulu lapho behlanganisa imininingwane yenqubo ye-electroplating. Izinsimbi ezinamandla aqinile σb>105kg/mm2 ezidingwa izindinganiso zamazwe ngamazwe kufanele zibe ngaphansi kwengcindezi yangaphambi kokucwenga kanye nokwelashwa kwe-post-plating dehydrogenation ngokufanele. Imboni yezokundiza yaseFrance idinga ukwelashwa okuhambisanayo kwe-dehydrogenation ezingxenyeni zensimbi ezinamandla okukhiqiza angu-σs>90kg/mm2.

Ngenxa yokuxhumana okuhle phakathi kwamandla ensimbi nobulukhuni, kunembile futhi kulula ukwahlulela ukuzwela kwe-hydrogen embrittlement yezinto ngobulukhuni kunamandla. Ngoba umdwebo womkhiqizo ophelele kanye nenqubo yokwenza imishini kufanele imakwe ngobulukhuni bensimbi. Ku-electroplating, sithole ukuthi ubulukhuni bensimbi ezungeze i-HRC38 buqale ukukhombisa ubungozi bokuphuka kwe-hydrogen embrittlement. Ezingxenyeni ezingaphezulu kune-HRC43, ukukhishwa kwe-hydrogen kufanele kucatshangelwe ngemva kokucwetshwa. Uma ubulukhuni bucishe bube yi-HRC60, ukwelashwa kwe-dehydrogenation kufanele kwenziwe ngokushesha ngemva kokwelashwa kwendawo, ngaphandle kwalokho izingxenye zensimbi zizoqhekeka phakathi namahora ambalwa.

Ukupakisha

Mayelana NATHI

* Umdwebo olandelayo ukhomba ama-incoterms ohwebo ahlukene. Sicela ukhethe oyithandayo.

OKUSHISAYO OKUDAYISWA

Ikhwalithi Okokuqala, Ukuphepha Kuqinisekisiwe